Managing Risk During Lean Improvements

- Raimund Laqua

- Aug 21, 2017

- 3 min read

Updated: Jun 9, 2020

LEAN approaches have been used across many industries for decades with great success. However, there are some industries were using LEAN for process improvement may end up exposing companies to: greater risk, loss of compliance, and reduced safety.

This is particularly true for the process industry. Fortunately, many companies in this sector already have the skills to effectively manage risk. They just need to apply these now to manage risk during LEAN improvements.

LEAN in the Process Industry

There have been several papers over the years written about the use of LEAN in the process industry. The one often cited was published in 2005 by T. Melton, "THE BENEFITS OF LEAN MANUFACTURING | What Lean Thinking has to Offer the Process Industries."

In this paper, Melton presents a compelling case for using LEAN in the process sector while acknowledging that the case for LEAN is not compelling for everyone. She asks the following question,

"With the benefits so apparently obvious the question has to be - what's stopping us?"

Here we are just over 10 years later and while LEAN continues to make in-roads this question is still pertinent and worth taking another look at.

Forces For and Against

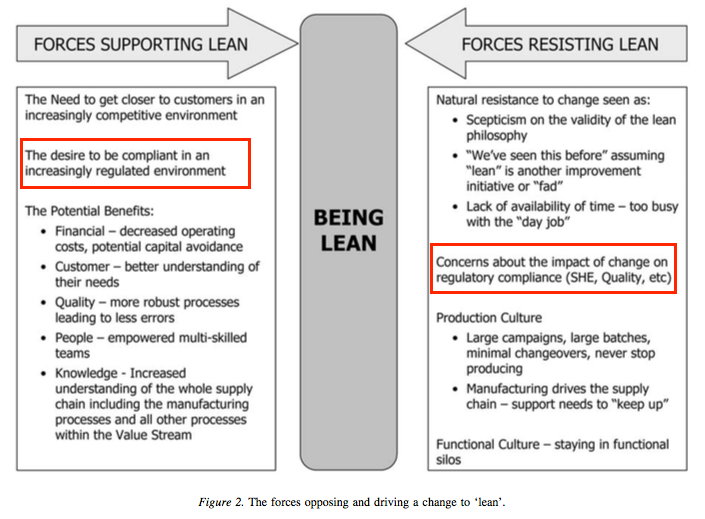

Melton presents the following force field diagram showing the supporting and resisting drivers within the manufacturing sector of process industries:

Let's look at how two of these forces (highlighted in RED) have changed since 2005:

Supporting Force: The desire to be compliant in an increasingly regulated environment

Since 2005, compliance has changed significantly. Not only has regulation continued to increase but it has also adopted a less prescriptive approach. Several of the recent changes have resulted from acknowledging that the majority of incidents, that precipitated the regulations in the first place, are better addressed by better systems than they are by legislating more prescriptive behaviors.

In addition, both standards and regulatory bodies have in previous years introduced updates that are: more systems oriented, risk based, and focused on outcomes. Many have also adopted the use of the Plan-Do-Check-Act (PDCA) cycle and the requirement for continuous improvement.

Focusing on the value stream along with continuous improvement are foundational to LEAN and in many ways benefit the process sector more today than in 2005. This is partly because the regulations themselves have adopted best practices from quality and LEAN thinking.

Resisting Force: Concerns about the impact of change on regulatory compliance (SHE, Quality, etc)

This concern is the flip side of the previous driver. Change of any kind, even those that improve the situation, can increase risk and create undesirable impacts.

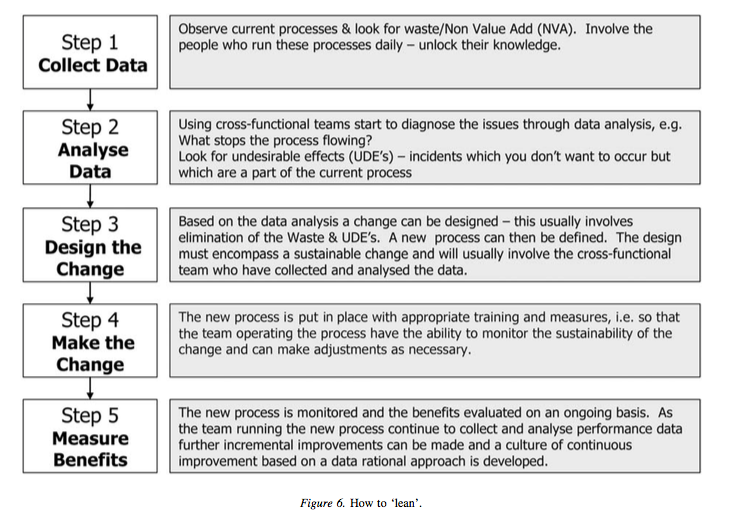

Melton outlines in her paper 5 steps to LEAN Thinking that provide a way to identify and manage undesirable effects:

Those familiar with process safety management (PSM) will recognize that these steps are very similar to the steps followed for Management of Change (MOC):

Initiation

Scoping

Change Design

Impact Analysis

Approvals

Implementation

Pre-Startup Safety Review

Close-Out

In recent years, risk assessment and risk management have become more fully embedded in safety processes to support not only PSM covered processes, but also procedure and organizational changes.

From a capabilities perspective, the ability to manage risks and changes has advanced significantly for those that have adopted these practices. Key capabilities include:

Cross Functional Teams

Engineering Problem Solving and Design

Risk Management

Change Management

Measurement and Verification

Monitor and Control

These capabilities effectively help organizations manage risk arising from changes to their facilities, manufacturing processes, and to the organization itself.

What we now need is a similar management of change process to manage risk during LEAN improvements.

LEAN Management of Change

LEAN offers significant benefits for companies who want to improve not only production but also their business processes. However, these changes must be done in a way that manages risk, keeps people and processes safe, and maintains compliance.

The process industry has had decades of experience managing risk and so this is not new to them. However, this maybe new to those who want to use LEAN to improve processes in companies that are highly regulated.

Risk management along with a structured change process is missing from many LEAN improvement initiatives. Understandably, this causes concern when applying LEAN to improve compliance programs and systems. In fact, it is a concern for making any changes to critical business processes.

Using Management of Change (MOC) best practices, along with skills already in place, will help to fill in the gaps to effectively manage risk during LEAN improvements. Doing so will alleviate many of the concerns and, finally, allow those in highly regulated industries to obtain more of the benefits from LEAN that other industries are currently enjoying.

Revisiting the Question

So back to Melton's question which I have revised,

With the benefits so apparently obvious, and with significant advancement in risk management, the question has to be - what's stopping us now?"